-

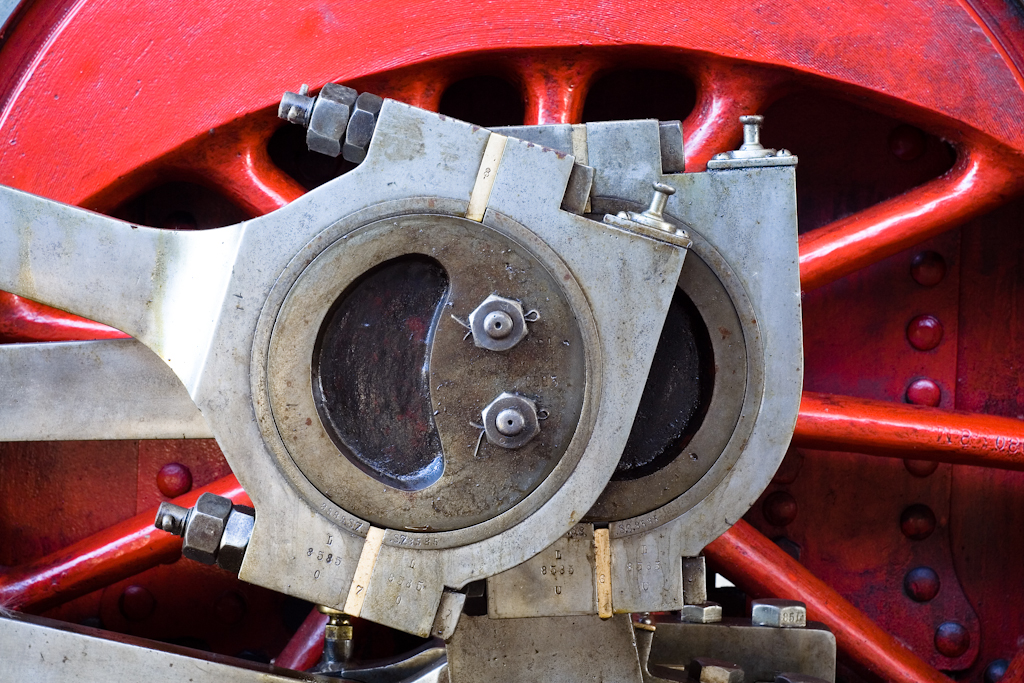

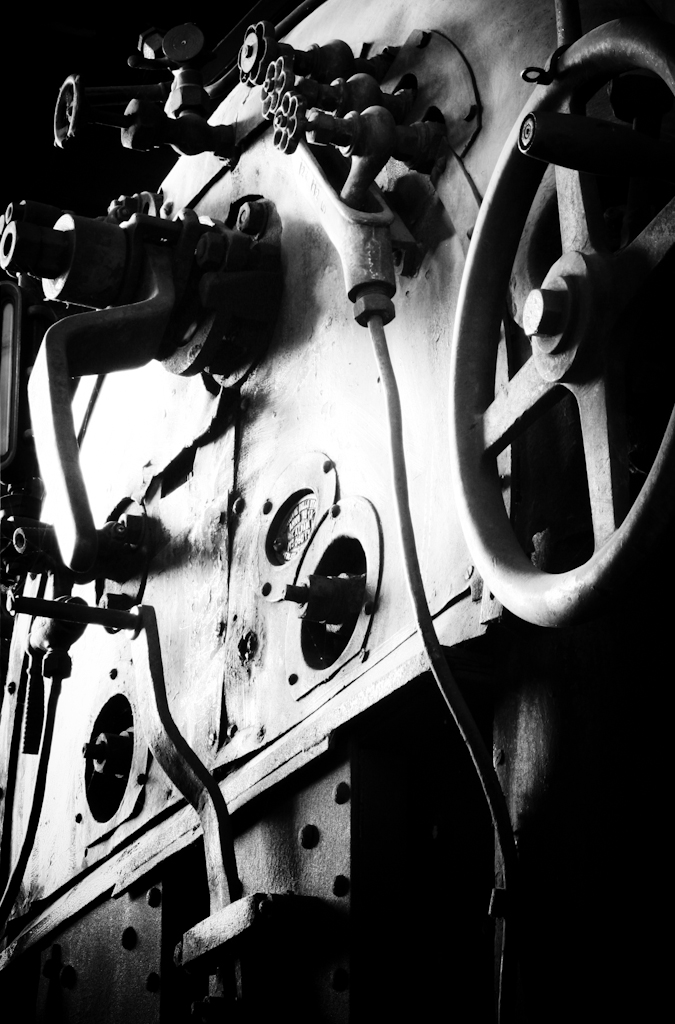

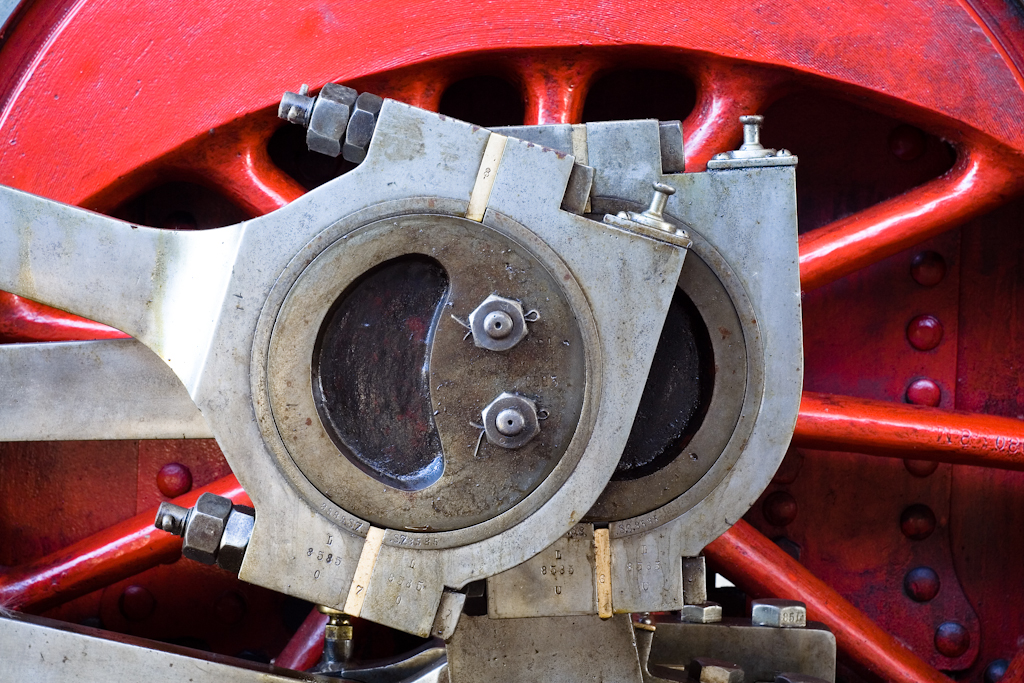

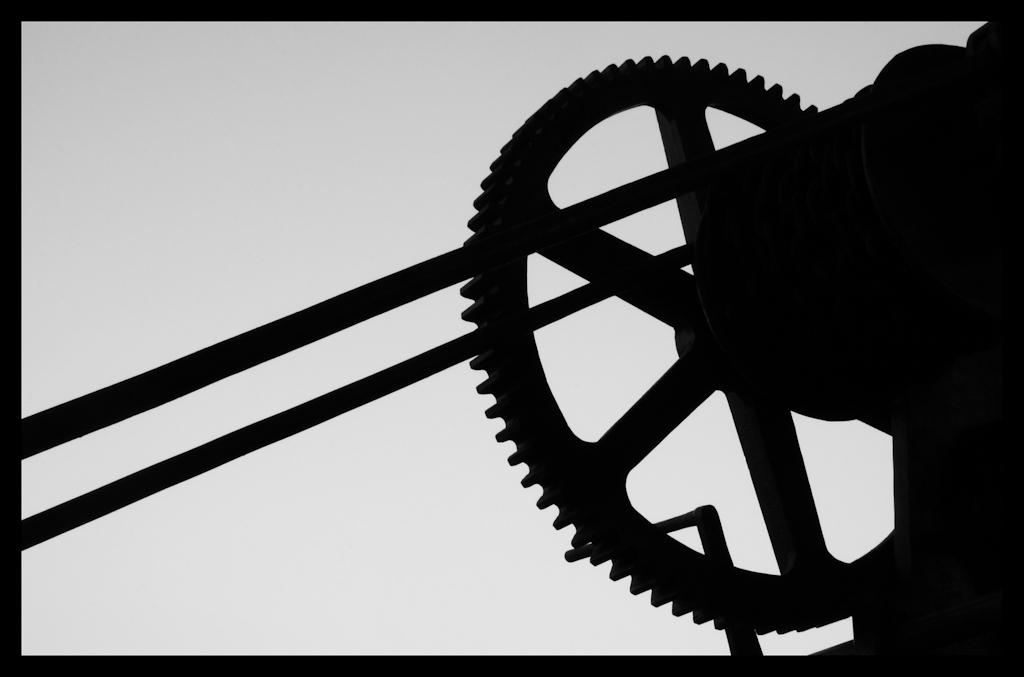

In 1851 Alfred Krupp invented the no-weld railway tyres to provide a replaceable wearing element on a costly wheel, which began the company's primary revenue stream, from sales to railways in the United States.

The tyre is fitted by heating to a controlled temperature, avoiding over-heating. This causes the tyre to expand. The wheel centre, usually already mounted on the axle, is lowered into the tyre which is flange side up. The tyre cools, and the retaining ring (a shaped steel bar rolled into a hoop) is fitted into the groove. Hydraulically operated rolls swage the groove down on to the retaining ring.

-

“A small number of locomotives have been equipped with a special incandescent circuit used to illuminate the running gear, etc. Where such an arrangement is made use of, a 16-candlepower incandescent lamp is placed inside of the reflector."

-

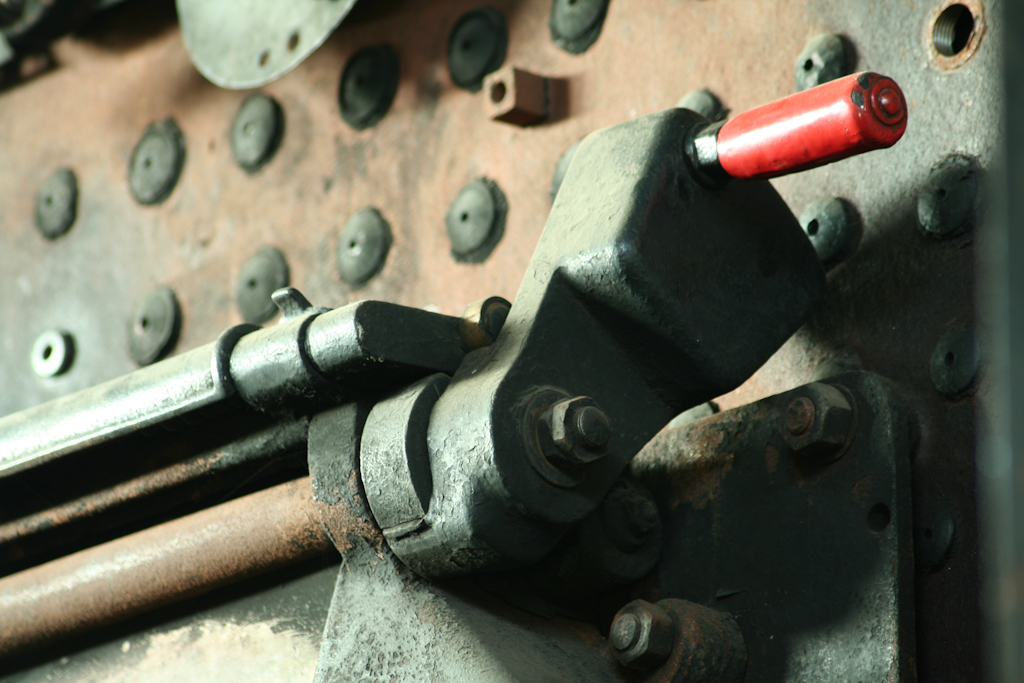

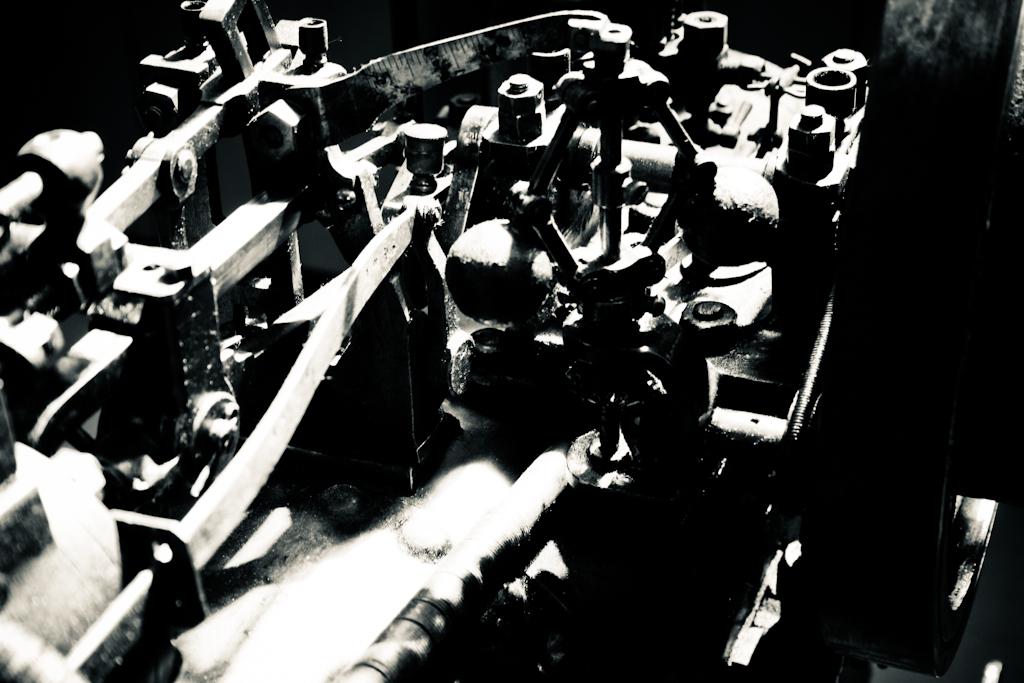

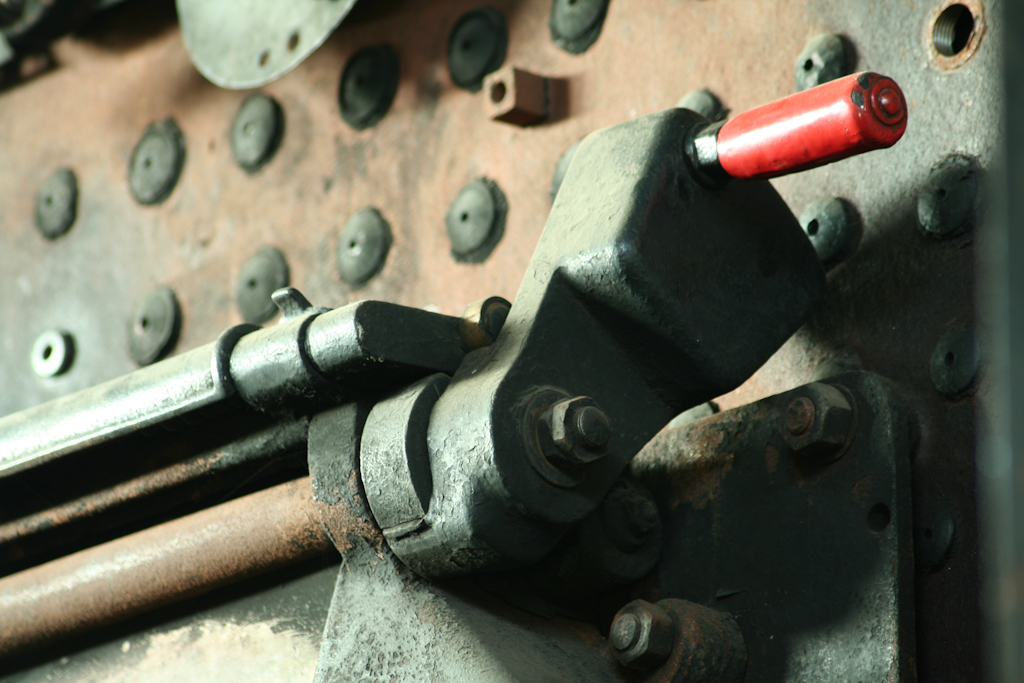

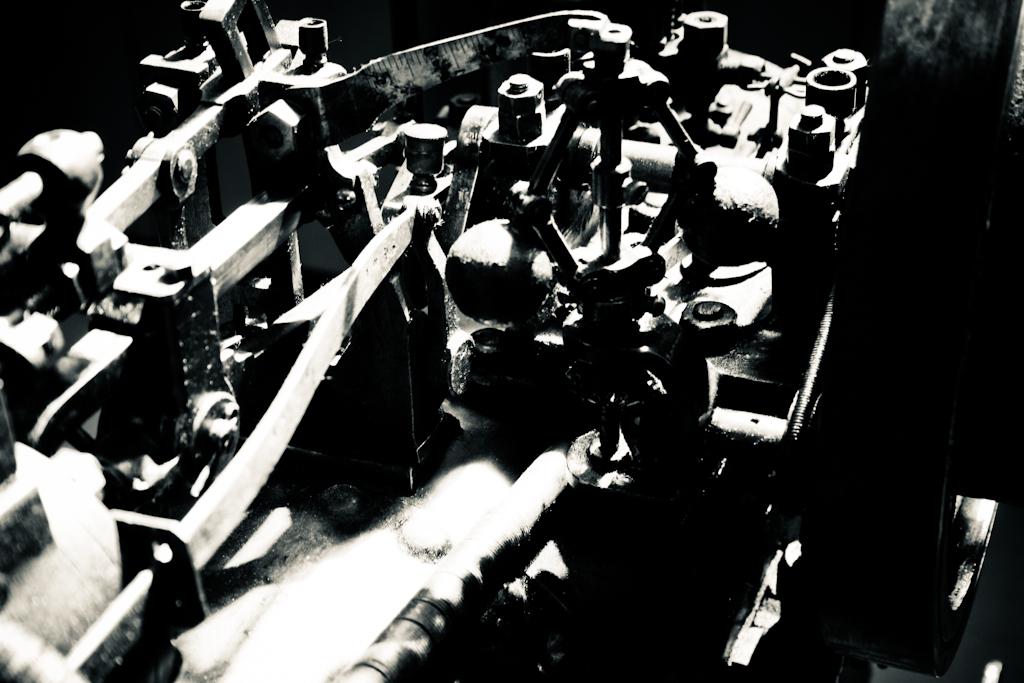

Early cars were coupled together using a link and pin system. Given that the pins had to be put into place and removed manually, coupling cars was a dangerous job that all too often led to the loss of fingers and hands.

-

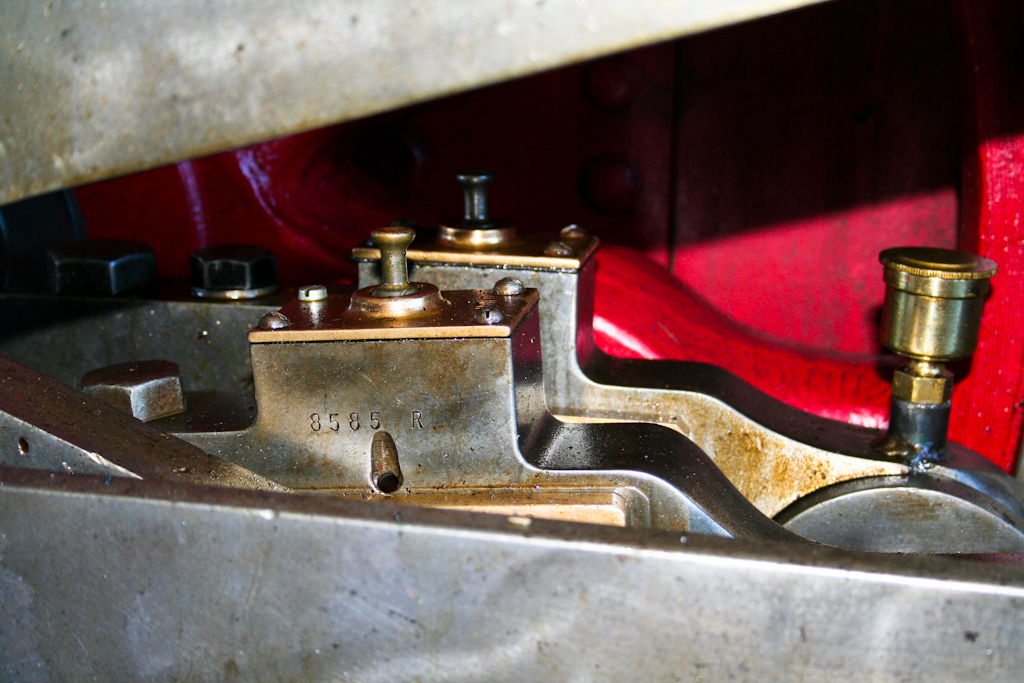

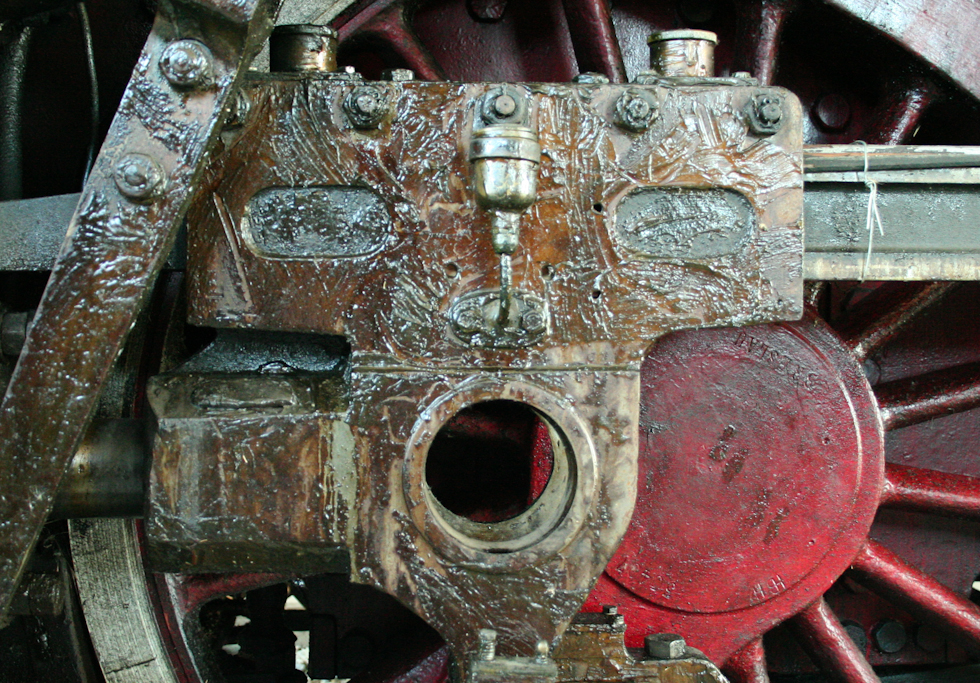

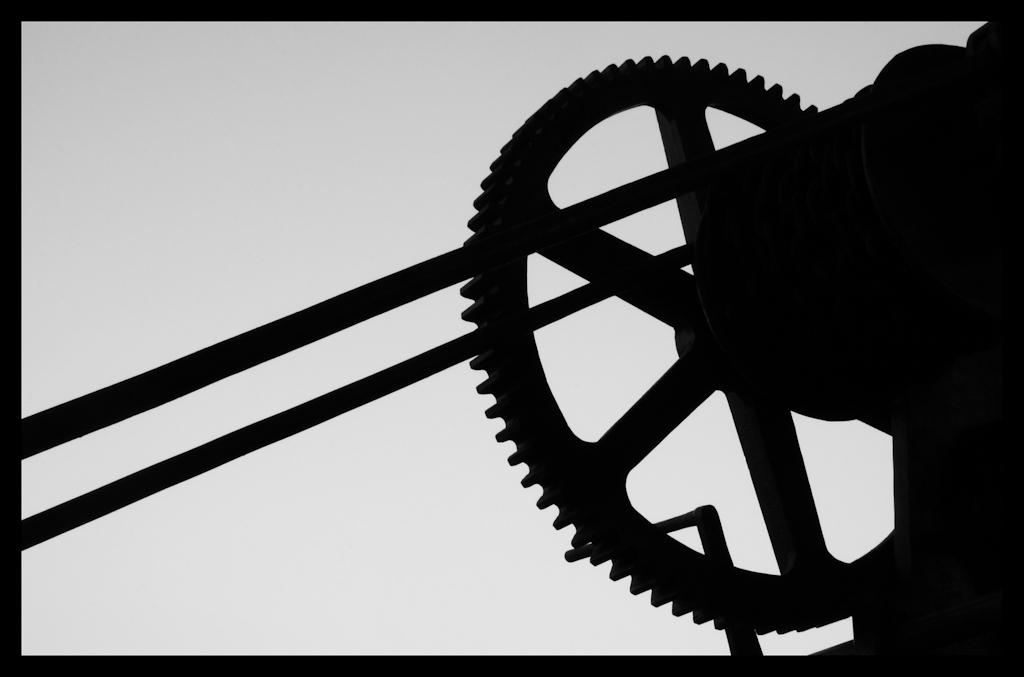

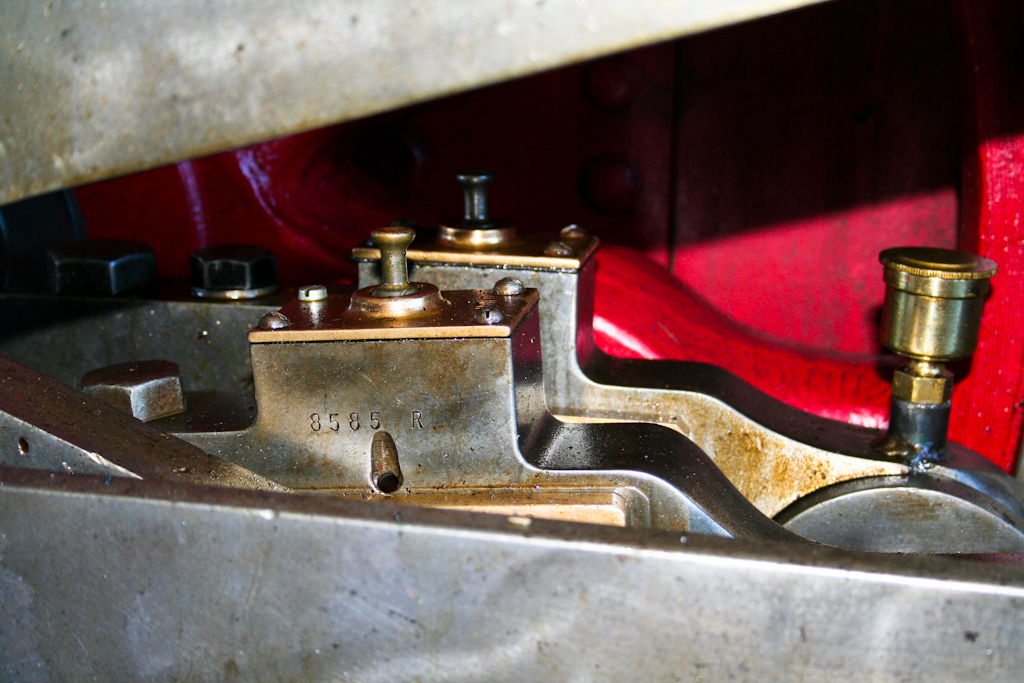

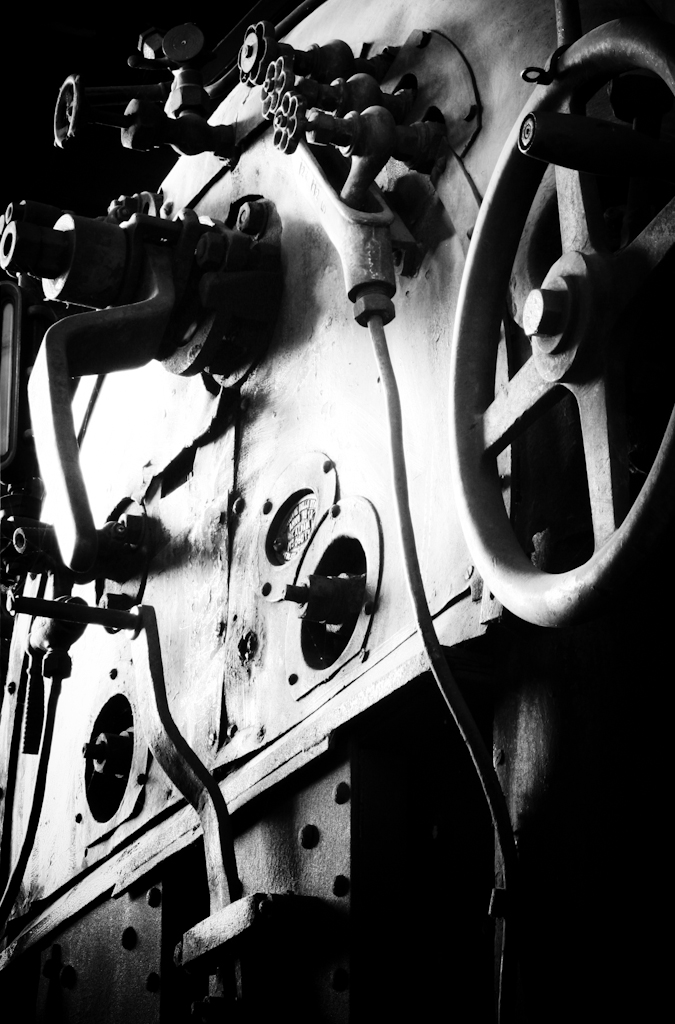

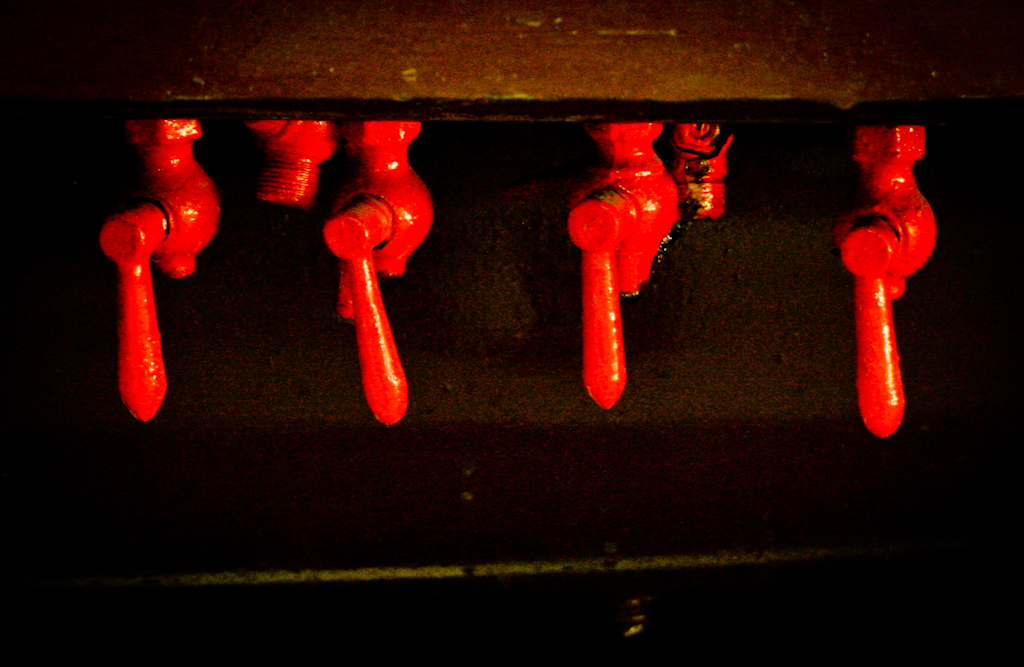

Crank pin and crosshead bearings carry small cup-shaped reservoirs for oil. These have feed pipes to the bearing surface that start above the normal fill level, or are kept closed by a loose-fitting pin, so that only when the locomotive is in motion does oil enter. In United Kingdom practice the cups are closed with simple corks, but these have a piece of porous cane pushed through them to admit air.

It is customary for a small capsule of pungent oil (aniseed or garlic) to be incorporated in the bearing metal to warn if the lubrication fails and excess heating or wear occurs.

-

-

-

-

-

-

-

-

-

-

-

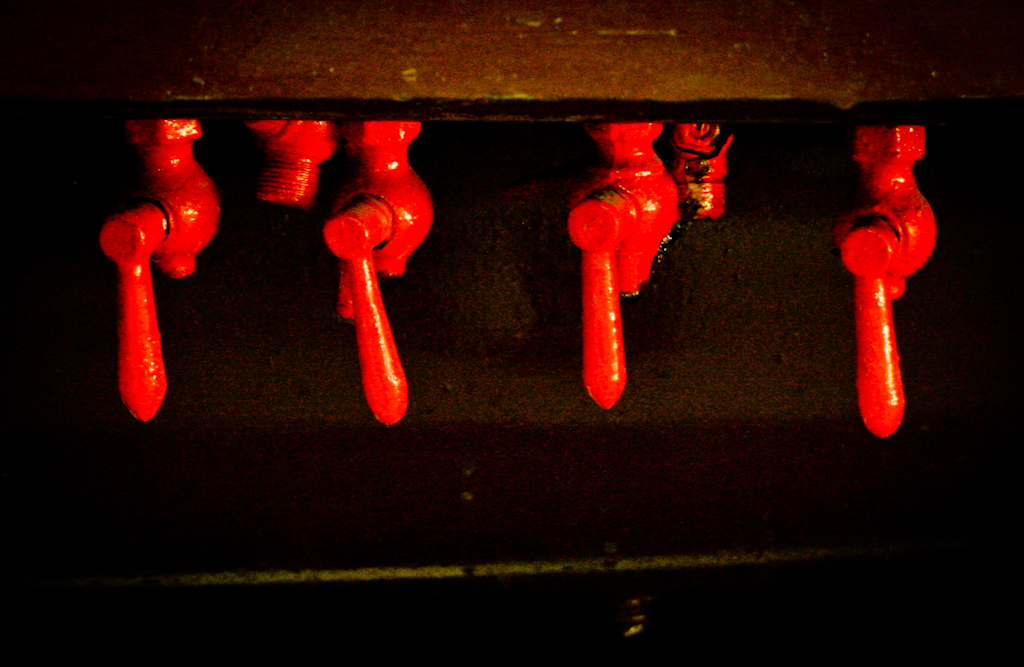

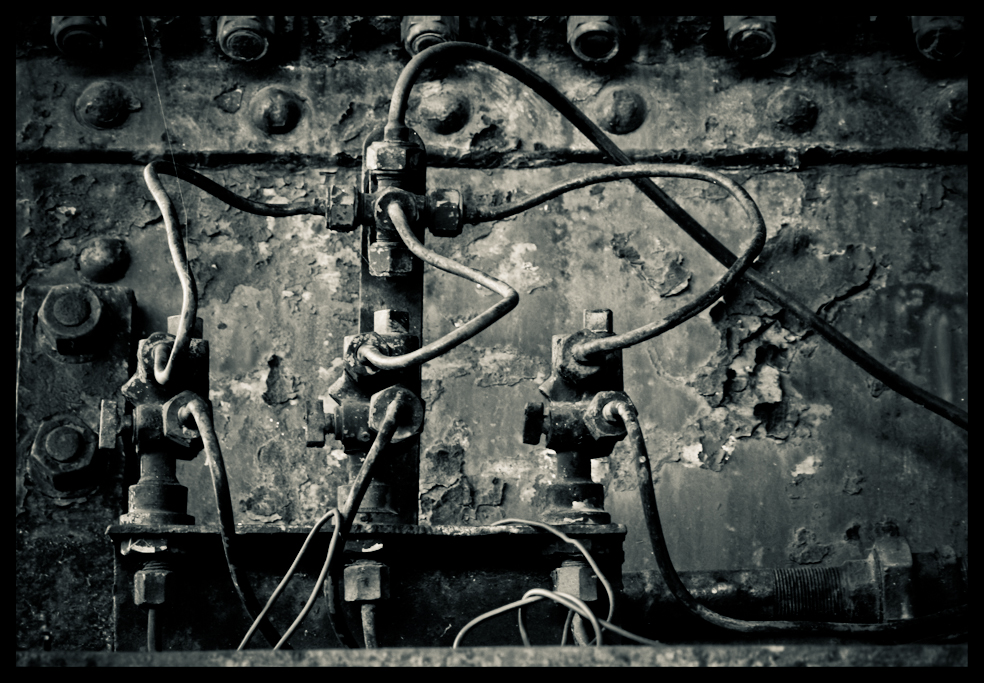

On railcars, an air brake is a conveyance braking system actuated by compressed air. Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on March 5, 1872.

The introduction of brakes to railcars necessitated the employment of additional crew members called brakemen, whose job it was to move from car to car and apply or release the brakes when signaled to do so by the engineer with a series of whistle blasts. Occasionally, derailments or collisions would occur because trains were not stopped in time.

When adopted, the Westinghouse system had a major effect on railroad safety. Reliable braking was assured, reducing the frequent accidents that plagued the industry.

-

-

-

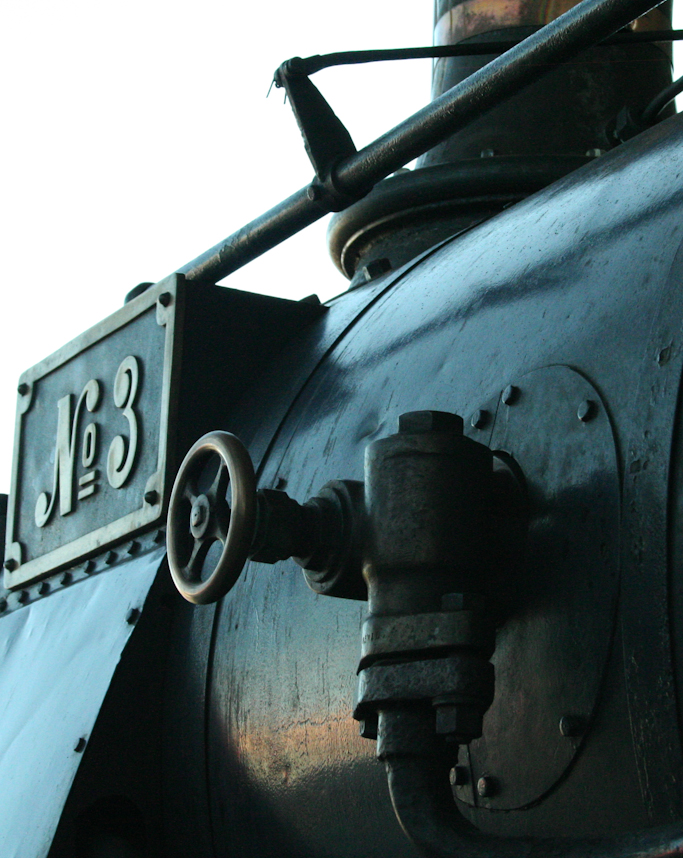

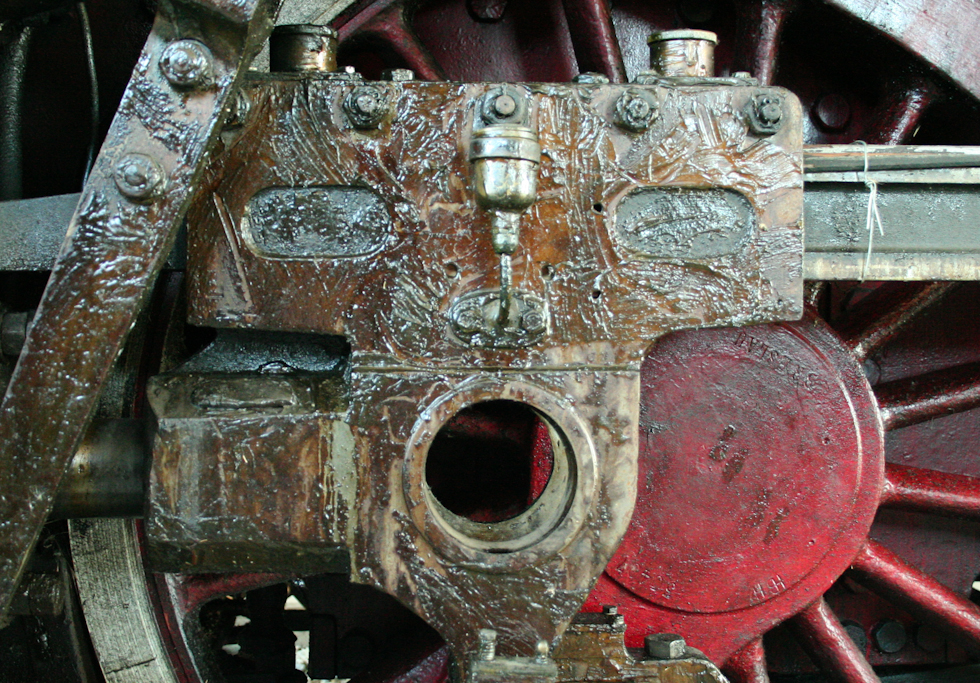

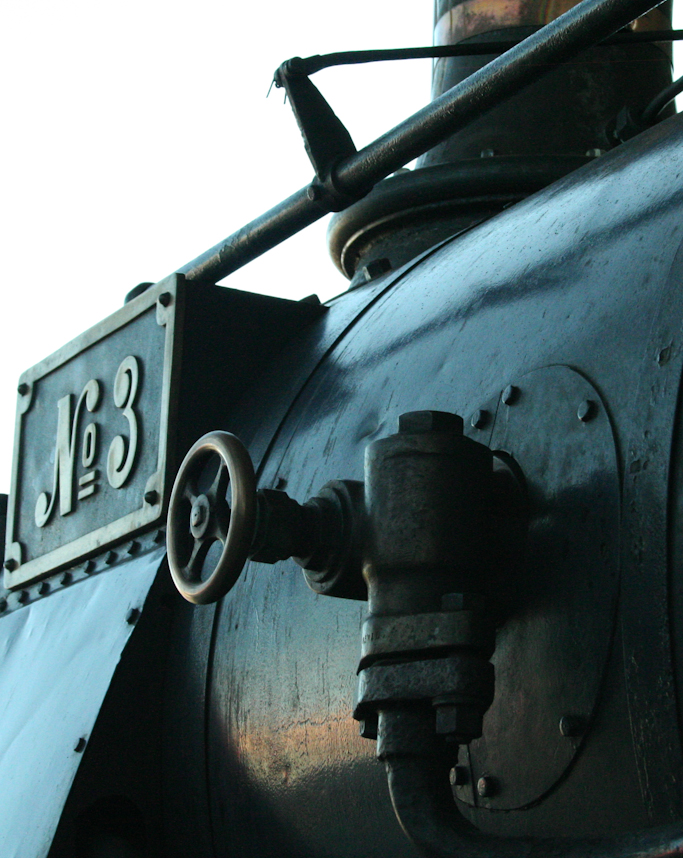

"Lucia", built in 1905-1913 by Hanomag Workshops.

After ending of World War I, a large number of locomotives, mostly coming from Prussian Kingdom Railways (KPEV) and from Austrian State Railways, particularly Südbahn, were given to Italy as compensation for war damages.

Some engines were put out of service in the late Thirties, while complete dismissing came in the early Fifties; Lucia, nevertheless, have been used up to 1973.

Thanks to some railway enthusiasts she is today in working conditions and operates sometimes historic steam trains.

-

-

-

-

-

-

-

-

-

Georg Christian Carl Henschel founded the factory in 1810 at Kassel. His son Carl Anton Henschel founded another factory in 1837. In 1848, the company began manufacturing locomotives.

Early in 1935, Henschel began manufacturing Panzer I tanks. During World War II in 1939-1940 it began large-scale production of the Panzer III, and the Tiger I from 1941. The company used forced labour extensively. The company's factories were among the most important bomber targets and were nearly completely destroyed.

Manufacturing began again in 1948. The Kassel facility still exists and is one of the world's largest manufacturers of locomotives.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

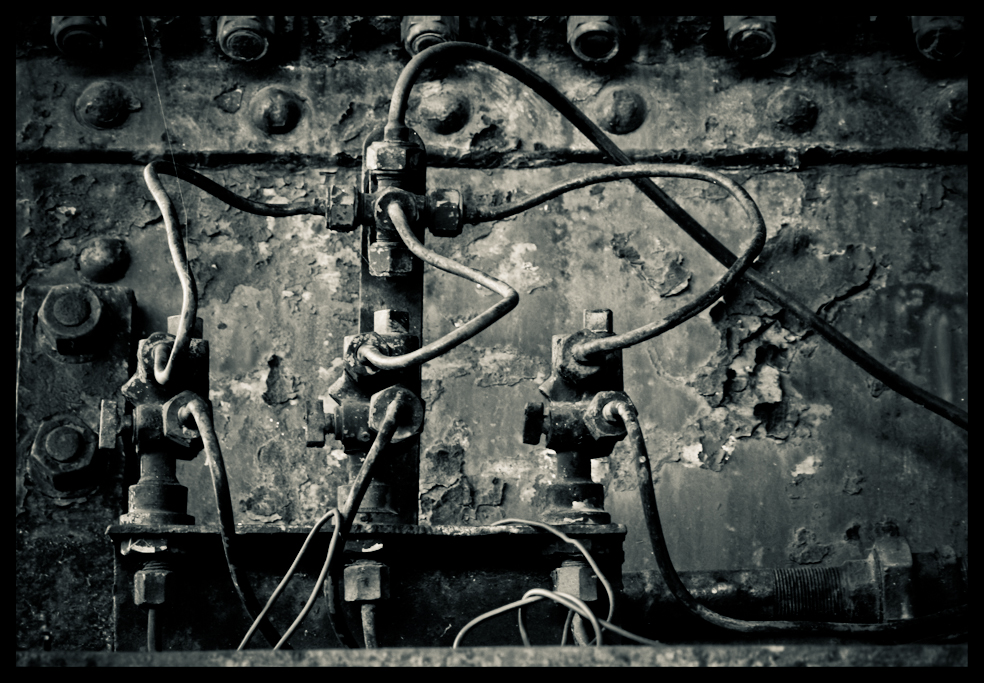

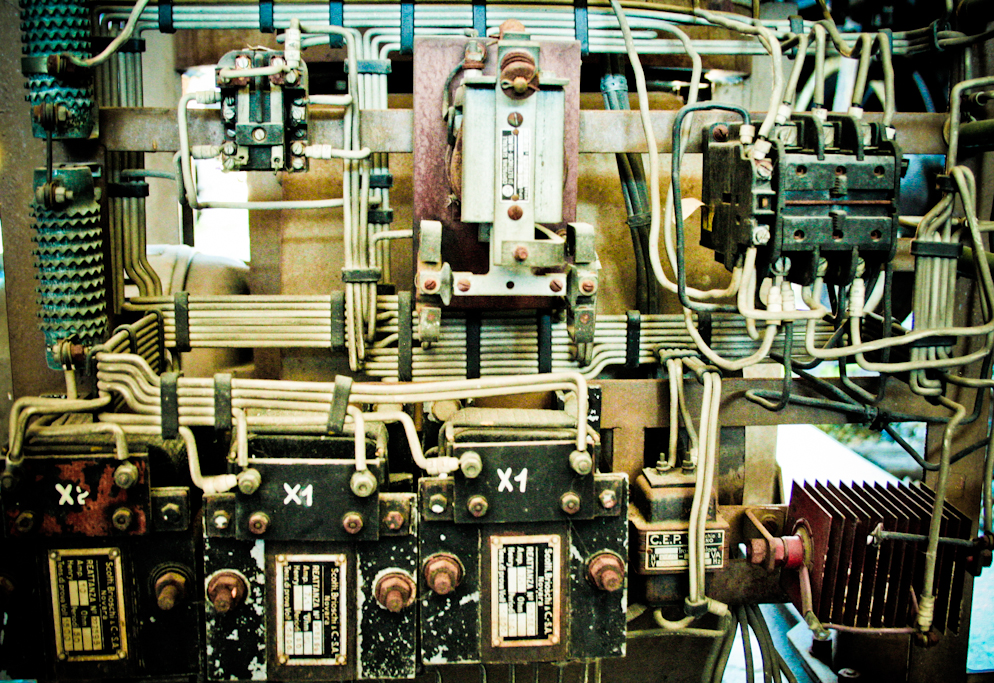

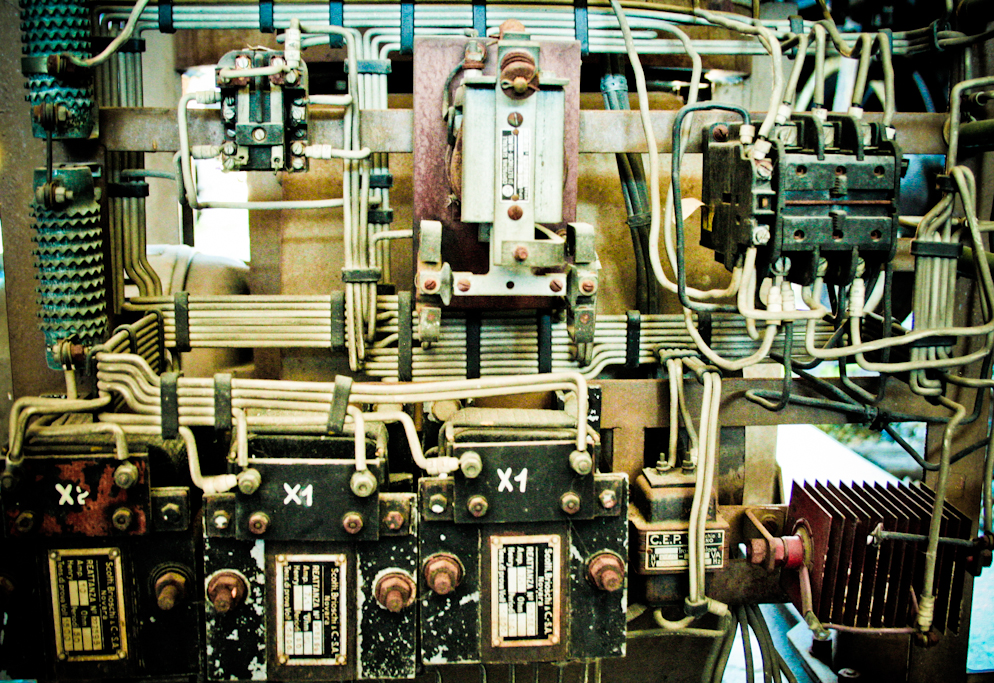

Then Electricity came... and everything changed.

-

Even the aestetics became quite different... as many of the mechanical parts needed to drive the engine do not need to be visible. No more grease and ashes, under the hood, but kilometers of wires...

-

In 1851 Alfred Krupp invented the no-weld railway tyres to provide a replaceable wearing element on a costly wheel, which began the company's primary revenue stream, from sales to railways in the United States.

In 1851 Alfred Krupp invented the no-weld railway tyres to provide a replaceable wearing element on a costly wheel, which began the company's primary revenue stream, from sales to railways in the United States. “A small number of locomotives have been equipped with a special incandescent circuit used to illuminate the running gear, etc. Where such an arrangement is made use of, a 16-candlepower incandescent lamp is placed inside of the reflector."

“A small number of locomotives have been equipped with a special incandescent circuit used to illuminate the running gear, etc. Where such an arrangement is made use of, a 16-candlepower incandescent lamp is placed inside of the reflector."

Early cars were coupled together using a link and pin system. Given that the pins had to be put into place and removed manually, coupling cars was a dangerous job that all too often led to the loss of fingers and hands.

Early cars were coupled together using a link and pin system. Given that the pins had to be put into place and removed manually, coupling cars was a dangerous job that all too often led to the loss of fingers and hands. Crank pin and crosshead bearings carry small cup-shaped reservoirs for oil. These have feed pipes to the bearing surface that start above the normal fill level, or are kept closed by a loose-fitting pin, so that only when the locomotive is in motion does oil enter. In United Kingdom practice the cups are closed with simple corks, but these have a piece of porous cane pushed through them to admit air.

Crank pin and crosshead bearings carry small cup-shaped reservoirs for oil. These have feed pipes to the bearing surface that start above the normal fill level, or are kept closed by a loose-fitting pin, so that only when the locomotive is in motion does oil enter. In United Kingdom practice the cups are closed with simple corks, but these have a piece of porous cane pushed through them to admit air.

On railcars, an air brake is a conveyance braking system actuated by compressed air. Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on March 5, 1872.

On railcars, an air brake is a conveyance braking system actuated by compressed air. Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on March 5, 1872.

"Lucia", built in 1905-1913 by Hanomag Workshops.

"Lucia", built in 1905-1913 by Hanomag Workshops.

Georg Christian Carl Henschel founded the factory in 1810 at Kassel. His son Carl Anton Henschel founded another factory in 1837. In 1848, the company began manufacturing locomotives.

Georg Christian Carl Henschel founded the factory in 1810 at Kassel. His son Carl Anton Henschel founded another factory in 1837. In 1848, the company began manufacturing locomotives.

Then Electricity came... and everything changed.

Then Electricity came... and everything changed. Even the aestetics became quite different... as many of the mechanical parts needed to drive the engine do not need to be visible. No more grease and ashes, under the hood, but kilometers of wires...

Even the aestetics became quite different... as many of the mechanical parts needed to drive the engine do not need to be visible. No more grease and ashes, under the hood, but kilometers of wires...